Get a 30-Day Trial

Experience Process Simulate with a free trial today.

REQUEST A FREE PRODUCT GUIDE

Get Product Guide

Discover more about Tecnomatix Process Simulate by exploring our downloads.

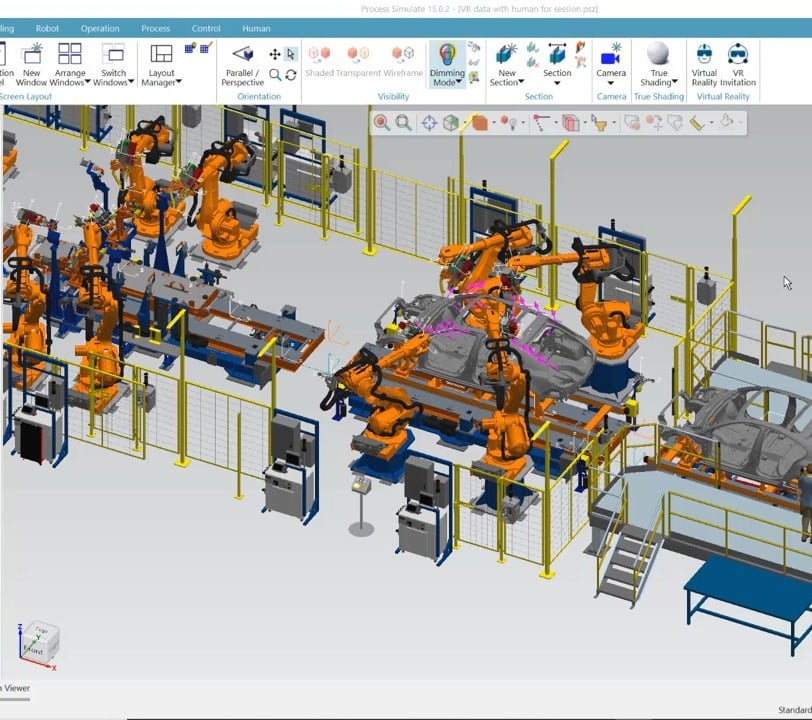

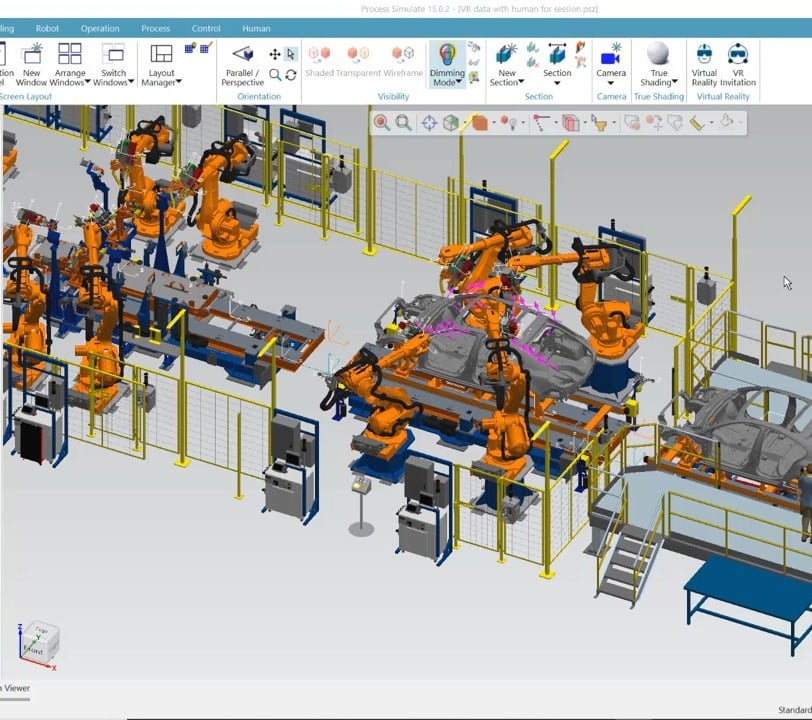

Process Simulate offers one unified platform for simulating Robotics, Human and AGV operations within the same 3D environment.

Process Simulate contains over 20 different robot controllers, making it an ideal fit for a multi-robot environment.

Process Simulate offers easy connection possibilities with various types of PLCs, Fleet Managers, external APIs, and more.

Reduce cycle time with state-of-the-art simulation and optimise your manufacturing processes.

Optimise design reviews in a collaborative 3D environment to shorten project lead times.

Process Simulate is seamlessly integrated with other solutions from the Siemens DISW portfolio, enabling the digital enterprise.

| NX MACH Designer |

NX Layout |

NX MACH 1 Design |

NX MACH 2 Product Design |

NX Cool Shape Design |

NX MACH 3 Product Design |

NX MACH 3 Industrial Design |

|

|---|---|---|---|---|---|---|---|

| Feature category | |||||||

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Experience Process Simulate with a free trial today.

Simulate entire processes like robotic operations, human assembly processes, or AGV trajectories at an early stage. Use collision detection in a 3D environment to spot and resolve potential issues, shortening start-up and standstill times during changeovers.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Virtual commissioning employs 3D simulation to create a digital copy of the facility, typically linked to the automation system, to virtually test every aspect of production before commencement or before making changes. For example, robots can be put into virtual operation, tested, and optimised before transferring the programs to the existing facility.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Experience Process Simulate with a free trial today.

Simulate entire processes like robotic operations, human assembly processes, or AGV trajectories at an early stage. Use collision detection in a 3D environment to spot and resolve potential issues, shortening start-up and standstill times during changeovers.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Virtual commissioning employs 3D simulation to create a digital copy of the facility, typically linked to the automation system, to virtually test every aspect of production before commencement or before making changes. For example, robots can be put into virtual operation, tested, and optimised before transferring the programs to the existing facility.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Process Simulate is a digital manufacturing solution used to validate processes in a 3D environment. It is a part of the Siemens Tecnomatix suite and assists companies in virtually planning, simulating, and optimising manufacturing processes.

Yes, Process Simulate is designed to integrate with various systems and can import data from CAD tools, allowing for a more synchronised workflow between design and manufacturing planning.

Process Simulate helps implement lean manufacturing principles by enabling the simulation and optimisation of manufacturing processes. It identifies and eliminates waste within the production cycle such as unnecessary motion.

While Process Simulate is user-friendly, new users can benefit from training to fully leverage all its features. We offer comprehensive training programs to help users maximise the software’s potential.

We provide robust support for Process Simulate users with our in-house support desk, providing technical assistance. Our team of consultants further supports users through coaching and training.