Get 30 Day NX CAM Trial

Experience NX CAM with a free trial today.

REQUEST A FREE PRODUCT GUIDE

Get Product Guide

Siemens NX CAM is the world leading integrated NC programming solution providing all your programming requirements within a single solution.

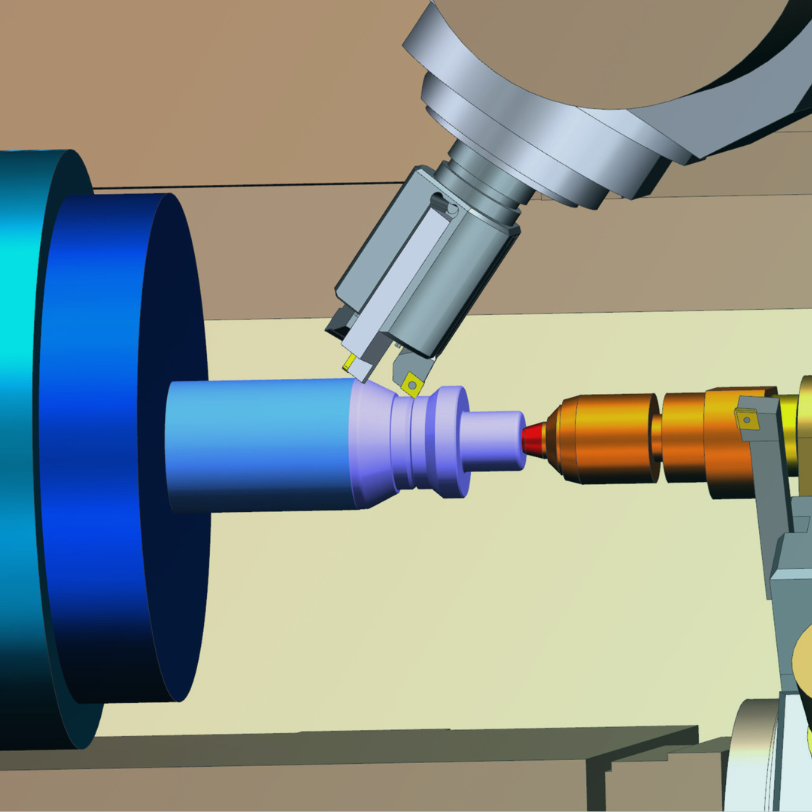

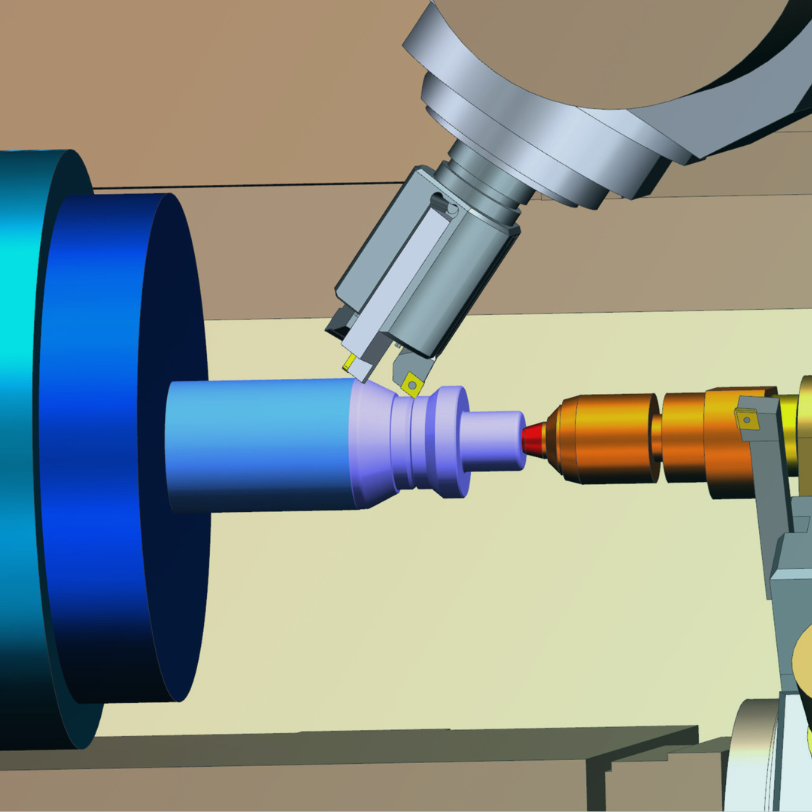

From 2.5-axis wire frame to complex simultaneous 5-axis milling or advances multi spindle mill/turn, NX CAM has the toolpaths and functionality to get the job done.

Streamline & automate NC programming, while reducing cycle time, using NX CAM.

Learn more about NX CAM by exploring our downloads. NX CAM is recognized as a leader in the CAM category - start your Journey today.

Automatically generate complete machining processes for prismatic parts of any complexity. Cut programming time by up to 90%.

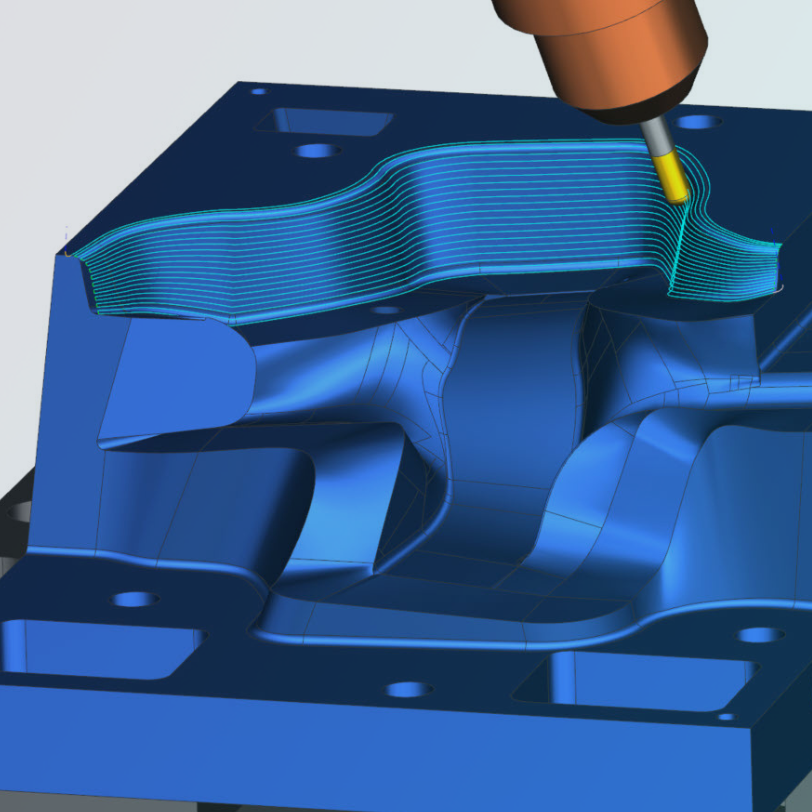

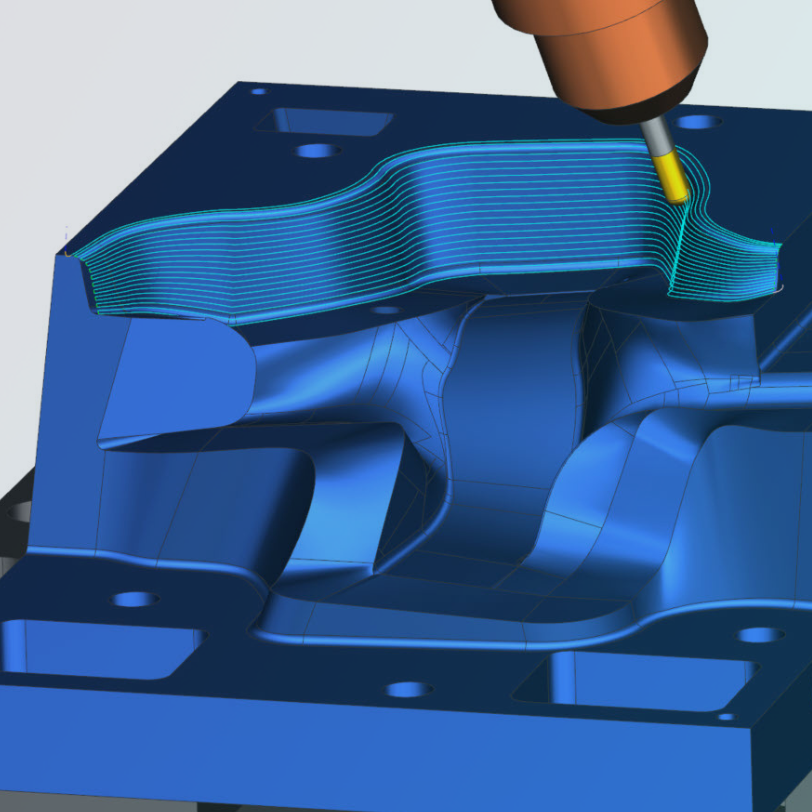

Manufacture higher quality molds, dies and electrodes using integrated CAD/CAM software with advanced machining capabilities.

Effectively manufacture complex parts using advanced 5-axis machining capabilities, reducing the number of operations and setups while improving part quality.

Generate validated, production-ready programs for your CNC machine tools using cloud-based toolpath postprocessing and integrated machining simulation.

Provide cutting methods for complex surfaces and demanding parts and include adaptive rouging and multi axis finishing strategies.

| NX MACH Designer |

NX Layout |

NX MACH 1 Design |

NX MACH 2 Product Design |

NX Cool Shape Design |

NX MACH 3 Product Design |

NX MACH 3 Industrial Design |

|

|---|---|---|---|---|---|---|---|

| Feature category | |||||||

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Experience NX CAM with a free trial today.

Generate high-performance machining operations to increase material removal rates, improve surface quality and extend tool life.

Complete jobs on spec and on time by using one CAD/CAM software to connect part manufacturing — from 3D models to precision machined parts.

Experience NX CAM with a free trial today.

Generate high-performance machining operations to increase material removal rates, improve surface quality and extend tool life.

Complete jobs on spec and on time by using one CAD/CAM software to connect part manufacturing — from 3D models to precision machined parts.

In the realm of precision machining, YouniQ Machining stands out as a trailblazer, redefining industry norms with their innovative approach and unparalleled efficiency. With a vision centered on minimizing human intervention, this unique startup, comprising just two individuals, has transformed the entire process into a seamless, software-driven operation. Embracing Siemens NX as their foundational tool, YouniQ has achieved remarkable milestones, slashing the industry-standard lead time from 6 weeks to an astonishing 2 working days. Their platform allows customers to swiftly upload 3D-CAD models, receiving digital quotes within an hour and enabling real-time verification through downloadable 3D models—an unprecedented feat. YouniQ's strategic alliance with cards, powered by NX CAD, NX CAM, and specialized extensions, epitomises a disruptive paradigm shift, showcasing an astounding 80% automation rate and spearheading a new era in precision manufacturing.

%2015%25-4.png)

In an era of demanding automotive manufacturing, Surtechno emerges as a pivotal player in mould modifications for major European automakers. By strategically pivoting to a niche market, they've redefined their focus on refining and adapting moulds, introducing a revolutionary approach. Leveraging NX CAD/CAM integration and expanding their infrastructure, Surtechno now pioneers in real-time design adjustments and testing, ensuring unparalleled quality control and swift adaptations, significantly reducing time-to-market while securing an extensive client base across Europe's leading suppliers. This case showcases their transformational journey towards precision and efficiency in the automotive moulding landscape.

%2015%25-5.png)

In a quest for innovation and enhanced production capabilities, New Wave Engineering, a leading machine fabrication firm, embarked on a transformative journey with NX CAM. Faced with the challenge of upgrading from I-DEAS, their prior software, compatibility was crucial, not just for their major automotive client but for a broader spectrum of industries. The strategic integration of NX CAM not only met these compatibility needs but also addressed escalating demands for intricate product development and expedited manufacturing. This integration enabled flawless collaboration between engineering and production, minimising errors, empowering unmanned operations, and fostering a 'first time right' production ethos. As a result, New Wave Engineering expanded its engineering horizons, attracted a diverse clientele, and significantly amplified its productivity through smarter, more efficient methodologies.

%2015%25-16.png)

NX CAM software offers flexible licensing options to suit your needs. Choose from perpetual, subscription, or token-based licenses, allowing scalability and cost-effectiveness. NX also supports floating and node-locked licenses.

NX CAM supports a wide range of machining operations, including 2.5-axis milling, 3-axis milling, multi-axis milling, turning, and wire EDM. This makes it suitable for various manufacturing applications.

Yes, NX CAM is designed to handle complex parts and intricate geometries. It supports advanced machining strategies for complex surfaces and features, making it suitable for industries like aerospace, automotive, and medical manufacturing.

NX CAM is often used in conjunction with other Siemens NX modules for design and analysis. Additionally, it can interface with various CAD systems and supports standard data exchange formats for seamless integration into the overall manufacturing workflow.

The cost of NX CAM software can vary significantly based on licensing options, the specific modules or features you require, and length of your planned usage. To get a custom quote, contact us. Our team can deliver quotes within 24 hours.